Chat

Welcome to Flux

Treat Flux like your intern. Tell it what you'd like to build and it'll get to work. You can also ask it questions, brainstorm ideas, and teach it your preferences. Learn More

Explain project

Write a project description

Find schematic issues

Create a test plan

Ready.

can you give any alternative of this transistor in smd

1y

For replacing the 2N2222 transistor in your ESP32-H2 Relay Board project with an SMD (Surface-Mount Device) alternative, a good choice would be the 2N2222A in an SOT-23 package. The 2N2222A is essentially the same as the 2N2222 in terms of functionality and specifications but comes in a surface-mount package suitable for more compact and modern PCB designs.

When selecting an SMD transistor, ensure it meets the following criteria as your project involves controlling a relay and may interface with other components that require certain specifications:

- Collector-Emitter Voltage ($V_{CE}$): Should be sufficient to handle the voltage levels in your project.

- Collector Current ($I_C$): Must be capable of handling the current requirements for driving the relay and any other loads connected to the transistor.

- Gain (hFE/Beta): Should have a comparable gain to ensure that the base current provided by driving circuits (like the ESP32-H2 or other control circuits) is sufficient to switch the transistor fully on.

Given the specifications of your project, the 2N2222A in an SOT-23 package fits well for general switching and amplification needs similar to the 2N2222 but in a smaller, surface-mount form factor. Always check the datasheet of the specific manufacturer's part you plan to use to ensure it meets your project's requirements, including thermal considerations and pinout compatibility.

Here's a general connection guideline assuming you're using the 2N2222A (SOT-23) as a replacement:

- Connect the Base (Pin 1 of the SOT-23) to the control signal, possibly through a resistor similar to how Q1:B is connected.

- Connect the Emitter (Pin 3 of the SOT-23) to ground (GND) or the reference point similar to Q1:E.

- The Collector (Pin 2 of the SOT-23) would go to the relay's coil or other load, similarly to Q1:C.

Make sure to review your circuit design in Flux for any necessary adjustments due to the footprint difference between the though-hole 2N2222 and the SOT-23 2N2222A.

1y

3

give me any smd alternative to this diode

1y

For replacing the 1N4007 diode in your project with a Surface-Mount Device (SMD) alternative, you can consider the M7 diode (SMD version of the 1N4007), which is very popular and widely used in various applications. The M7 diode provides similar electrical characteristics to the 1N4007, such as a maximum repetitive reverse voltage of 1000V and a forward current of 1A, which should be suitable for most applications originally designed with the 1N4007 in mind.

Here are some details about the M7 diode:

- MPN: M7 (also known as S1M)

- Package: DO-214AC (SMA)

- Peak Repetitive Reverse Voltage: 1000V

- Max Forward Current: 1A

- **Max Forward Voltage (at1A): 0.7V

- Manufacturer: Various

Remember to check the footprint of the M7 diode against your current PCB layout in Flux to ensure compatibility, as SMD components have different physical sizes and pad arrangements compared to their through-hole counterparts.

1y

4

RST

12V

C3

Capacitance

10u F

3V3

U2

Reviews

Design Rule Checks

Overlapping Copper • 11

Des | Net | Des | Net | ... | |

|---|---|---|---|---|---|

Missing Footprints

Reports parts that have no footprint.

Invalid Layer

Reports nodes that are assigned to a layer that doesn't exist in the layout stackup.

Airwires • 12

Deprecated Rules

Reports nodes that are using rules that are not supported anymore.

Layers with Multiple Fills

Reports layers that have multiple copper fills of different nets. Make sure the Connected Layers rule value of nets with fills is valid.

Floating Copper • 1

Name | |

|---|---|

Protected Intrusions

Reports intrusions from objects of other nets into polygons or fills that have the Protected layout rule applied.

System Checks

Auto-Layout

BetaReports issues with Auto-Layout if Flux cannot route something or must ignore a configuration.

Passive Components

Resistor Power Rating

BetaChecks that the power traveling across a given resistor is under its rating with 50% headroom.

Learn morePull Up/Pull Down Presence

BetaChecks that IC pins that require pull up or pull down resistors have them.

Learn moreCapacitor Voltage Rating

BetaChecks that capacitors have appropriate voltage ratings to prevent overheating and ensure reliable circuit operation.

- Wirelessly connects nets on schematic. Used to organize schematics and separate functional blocks. To wirelessly connect net portals, give them same designator. #portaljharwinbarrozo43.0M

- Wirelessly connects power nets on schematic. Identical to the net portal, but with a power symbol. Used to organize schematics and separate functional blocks. To wirelessly connect power net portals, give them the same designator. #portal #powerjharwinbarrozo11.4M

- A generic fixed resistor for rapid developing circuit topology. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard resistor values: 1.0Ω 10Ω 100Ω 1.0kΩ 10kΩ 100kΩ 1.0MΩ 1.1Ω 11Ω 110Ω 1.1kΩ 11kΩ 110kΩ 1.1MΩ 1.2Ω 12Ω 120Ω 1.2kΩ 12kΩ 120kΩ 1.2MΩ 1.3Ω 13Ω 130Ω 1.3kΩ 13kΩ 130kΩ 1.3MΩ 1.5Ω 15Ω 150Ω 1.5kΩ 15kΩ 150kΩ 1.5MΩ 1.6Ω 16Ω 160Ω 1.6kΩ 16kΩ 160kΩ 1.6MΩ 1.8Ω 18Ω 180Ω 1.8KΩ 18kΩ 180kΩ 1.8MΩ 2.0Ω 20Ω 200Ω 2.0kΩ 20kΩ 200kΩ 2.0MΩ 2.2Ω 22Ω 220Ω 2.2kΩ 22kΩ 220kΩ 2.2MΩ 2.4Ω 24Ω 240Ω 2.4kΩ 24kΩ 240kΩ 2.4MΩ 2.7Ω 27Ω 270Ω 2.7kΩ 27kΩ 270kΩ 2.7MΩ 3.0Ω 30Ω 300Ω 3.0KΩ 30KΩ 300KΩ 3.0MΩ 3.3Ω 33Ω 330Ω 3.3kΩ 33kΩ 330kΩ 3.3MΩ 3.6Ω 36Ω 360Ω 3.6kΩ 36kΩ 360kΩ 3.6MΩ 3.9Ω 39Ω 390Ω 3.9kΩ 39kΩ 390kΩ 3.9MΩ 4.3Ω 43Ω 430Ω 4.3kΩ 43KΩ 430KΩ 4.3MΩ 4.7Ω 47Ω 470Ω 4.7kΩ 47kΩ 470kΩ 4.7MΩ 5.1Ω 51Ω 510Ω 5.1kΩ 51kΩ 510kΩ 5.1MΩ 5.6Ω 56Ω 560Ω 5.6kΩ 56kΩ 560kΩ 5.6MΩ 6.2Ω 62Ω 620Ω 6.2kΩ 62KΩ 620KΩ 6.2MΩ 6.8Ω 68Ω 680Ω 6.8kΩ 68kΩ 680kΩ 6.8MΩ 7.5Ω 75Ω 750Ω 7.5kΩ 75kΩ 750kΩ 7.5MΩ 8.2Ω 82Ω 820Ω 8.2kΩ 82kΩ 820kΩ 8.2MΩ 9.1Ω 91Ω 910Ω 9.1kΩ 91kΩ 910kΩ 9.1MΩ #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed capacitor ideal for rapid circuit topology development. You can choose between polarized and non-polarized types, its symbol and the footprint will automatically adapt based on your selection. Supported options include standard SMD sizes for ceramic capacitors (e.g., 0402, 0603, 0805), SMD sizes for aluminum electrolytic capacitors, and through-hole footprints for polarized capacitors. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard capacitor values: 1.0pF 10pF 100pF 1000pF 0.01uF 0.1uF 1.0uF 10uF 100uF 1000uF 10,000uF 1.1pF 11pF 110pF 1100pF 1.2pF 12pF 120pF 1200pF 1.3pF 13pF 130pF 1300pF 1.5pF 15pF 150pF 1500pF 0.015uF 0.15uF 1.5uF 15uF 150uF 1500uF 1.6pF 16pF 160pF 1600pF 1.8pF 18pF 180pF 1800pF 2.0pF 20pF 200pF 2000pF 2.2pF 22pF 20pF 2200pF 0.022uF 0.22uF 2.2uF 22uF 220uF 2200uF 2.4pF 24pF 240pF 2400pF 2.7pF 27pF 270pF 2700pF 3.0pF 30pF 300pF 3000pF 3.3pF 33pF 330pF 3300pF 0.033uF 0.33uF 3.3uF 33uF 330uF 3300uF 3.6pF 36pF 360pF 3600pF 3.9pF 39pF 390pF 3900pF 4.3pF 43pF 430pF 4300pF 4.7pF 47pF 470pF 4700pF 0.047uF 0.47uF 4.7uF 47uF 470uF 4700uF 5.1pF 51pF 510pF 5100pF 5.6pF 56pF 560pF 5600pF 6.2pF 62pF 620pF 6200pF 6.8pF 68pF 680pF 6800pF 0.068uF 0.68uF 6.8uF 68uF 680uF 6800uF 7.5pF 75pF 750pF 7500pF 8.2pF 82pF 820pF 8200pF 9.1pF 91pF 910pF 9100pF #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed inductor for rapid developing circuit topology. *You can now change the footprint and 3D model at the top level anytime you want. This is the power of #genericsjharwinbarrozo15.0k

- An electrical connector acting as reusable interface to a conductor and creating a point where external circuits can be connected.Terminal

- 47 kOhms ±5% 0.125W, 1/8W Chip Resistor 0805 (2012 Metric) Automotive AEC-Q200 Thick Film #forLedBlinkjharwinbarrozo1.2M

- 10uF Capacitor Aluminum Polymer 20% 16V SMD 5x5.3mm #forLedBlink #commonpartslibrary #capacitor #aluminumpolymer #radialcanjharwinbarrozo1.2M

- Yellow 595nm LED Indication - Discrete 1.7V 1206 (3216 Metric) #forLedBlinkjharwinbarrozo1.1M

Inspect

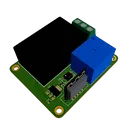

ESP32-H2 Relay Board qbfF

Controls

Properties

Availability & Pricing

| Distributor | Qty 1 | |

|---|---|---|

| Digi-Key | $7.87–$8.44 | |

| LCSC | $5.62–$5.76 | |

| Mouser | $7.74 | |

Assets

- ESP32-H2 Relay Board.png

id=ESP32-H2 Relay Board

Thumbnail

Welcome 👋

Flux helps you build PCBs faster with an AI teammate!

Create your account to collaborate, stay updated, fork your own version, and get instant answers from our AI agent.

zainey4

zainey4

copilot

zainey4

copilot

zainey4

copilot

zainey4

copilot

zainey4

copilot

- Drain to the relay coil's positive terminal.

- Source to ground.

- Gate through a resistor (to limit the current spike) connected to the optocoupler's output. The resistor can be around 1kΩ to 10kΩ.

Implementation Tips:zainey4

copilot

- Base Resistor ($R_{B}$) Value: Choose a ~360Ω or 370Ω resistor as the base resistor for the 2N2222 to drive the SRD-05VDC-SL-C. This will ensure the transistor is in saturation, allowing it to switch the relay effectively.

Additional Considerationzainey4

copilot

- Reliable Switching: The NPN transistor (e.g., 2N2222), driven correctly, ensures that the relay can be reliably switched on and off. By providing sufficient current to the relay coil that the direct GPIO pin or optocoupler output might not achieve, the transistor ensures that the relay is fully activated when needed.

- Increased Isolation: When used in conjunction with an optocoupler, the transistor further isolates the low-power control circuitry from the higher-power loads switched by the relay, enhancing safety.

- Protection for Control Circuitry: The transistor acts as a buffer between the control circuitry and the relay, protecting the former from potential high voltage or current spikes.

Benefits of Adding a Flyback Diode:- Voltage Spike Suppression: When the relay is deactivated, the collapsing magnetic field in the coil generates a high voltage spike that can damage the driving transistor and other components. The flyback diode (e.g., 1N4007) across the relay coil clamps these voltage spikes, protecting the components.

- Increased Component Lifespan: By suppressing voltage spikes, the diode reduces wear on the transistor and relay, potentially increasing the lifespan of these components.

Potential Considerations After the Addition:- Correct Component Orientation: Ensure the flyback diode is correctly oriented, with the cathode connected to the positive side of the relay coil and the anode to the negative side. Incorrect orientation will not provide the intended protection.

- Base Resistor Value: The calculated value for the base resistor ensures the transistor is saturated; however, confirm this value works as intended in your specific context. Component tolerances and variations in operating conditions can affect performance.

- Transistor Specifications: Verify that the chosen transistor meets all your requirements, including maximum collector current and collector-emitter voltage, to handle the relay coil's demands without issues.

Circuit Analysis for Potential Problems:- Power Supply Adequacy: Ensure your power supply can handle the additional current draw from the relay coil and has sufficient overhead for stable operation.

- Thermal Management: Check if the transistor or any other component heats up more than expected during operation, indicating excessive current or a potential mismatch in component specifications.

- Complete Activation/Deactivation: Test to ensure the relay reliably activates and deactivates in all expected operational scenarios, particularly under varying load conditions.

Conclusionzainey4

copilot

- Package: The MMBT2222A comes in an SOT-23 package, a popular small footprint surface-mount option.

- Collector Current: It can handle a collector current (Ic) of up to 600mA, making it suitable for a wide range of applications, including driving relays.

- Voltage Ratings: It has similar voltage ratings, with Vceo (collector-emitter voltage) around 40V, which is ample for most low to medium voltage applications.

- Gain (hFE): Its DC current gain (hFE) is within a similar range, ensuring it can be driven by low input currents similar to the 2N2222.

Considerations for Replacement:- Check the Pinout: Ensure that the pinout matches or is appropriately adapted to your circuit design. The SOT-23 package will have a different pin configuration than the TO-92.

- Thermal Performance: SMD components may have different thermal dissipation characteristics compared to their through-hole counterparts. Ensure the chosen SMD part can handle the thermal requirements of your application.

- Drive Characteristics: Verify the base current requirement and ensure that your drive circuit (optocoupler, microcontroller, etc.) can provide the necessary current to switch the transistor fully into saturation when necessary.

Example Connection for Relay Drive: