3D PCB View Inquiry

0:33

General (prev)

Project

Help

Reading docs for: "3D view"

Evaluating relevant help entries.

Here’s what the Flux documentation says about the 3D PCB view:

What About 3D View?The 3D PCB view is optimized for a high-level, realistic visualization of your board. It doesn’t include layer selection controls. Here’s what you can and can’t configure:What You Can Do in 3D View:

- Rotate, pan, and zoom the board to inspect the overall geometry.

- See stacked vias, components, and general board structure.

- Visually confirm copper pours and silkscreen placement.

What You Can’t Do:

- You cannot toggle individual layer visibility.

- You cannot hide or isolate specific copper layers or metadata layers (like net or DRC overlays).

If you need to inspect specific layers or debug layer-specific issues, switch back to the 2D view using the View Mode toggle in the top toolbar.

139 days

0:35

General (prev)

Chat History

Project

Help

Reading docs for: "How to switch to the 3D PCB view in Flux"

I couldn’t find specific instructions for switching to the 3D PCB view in the Flux documentation. It looks like the feature may not be documented there.

You can browse the Flux documentation directly for more details:

If you believe this feature should be documented, please let me know!

Locate View Mode

Check 3D support

Keyboard shortcut

Export board

Enable 3D plugin

139 days

Ready.

recommend a replacement for Q1.

1y

For a replacement of Q1, which is designated as SIR680ADP-T1-RE3 (a Vishay model), you'll want a MOSFET that matches or exceeds the original device's specifications for your PWM controller application. The SIR680ADP-T1-RE3 is a 60V, 80A, N-Channel Power MOSFET. When looking for a replacement, consider the following specifications:

- Drain-to-Source Voltage (VDS): Equal or higher than 60V.

- Continuous Drain Current (ID): Equal or higher than 80A.

- Gate Threshold Voltage (VGS(th)): Similar to ensure compatibility with drive voltage.

- R_DS(on): As low as possible to minimize on-state losses.

- Package: Make sure the replacement fits your PCB layout, SIR680ADP-T1-RE3 is in a PowerPAK SO-8 package.

One possible replacement, considering the requirements, is the IRLB8743PbF from Infineon Technologies. Its key features include:

- Drain-to-Source Voltage (VDS): 30V (Lower than SIR680ADP but might be sufficient depending on your application's voltage requirements. If your application requires close to 60V, consider an alternative recommendation.)

- Continuous Drain Current (ID): 160A (providing ample capability for high current applications).

- R_DS(on): 4.5 mΩ (max at 10V V_GS), providing low conduction losses.

- Package: TO-220, which is different from the PowerPAK SO-8 of SIR680ADP-T1-RE3, so check if the package difference is acceptable for your layout.

If the 30V VDS of the IRLB8743PbF is not suitable due to higher voltage requirements in your project, another alternative is the IRFZ44N:

- Drain-to-Source Voltage (VDS): 55V (Closer to the original spec).

- Continuous Drain Current (ID): 49A.

- R_DS(on): 17.5 mΩ (max at 10V V_GS).

- Package: TO-220.

Each replacement option has its own advantages and trade-offs, so the final decision should be based on the specific requirements of your project, such as the maximum operating voltage and the physical layout constraints. Always cross-check the datasheet of the potential replacement to ensure it meets your circuit's requirements.

1y

Someone is typing...

5

crea un circuito de una señal pwm

1y

Para crear un circuito de señal PWM (Pulse Width Modulation), normalmente utilizamos un temporizador 555 en configuración astable. En este circuito, el ciclo de trabajo se puede ajustar utilizando un potenciómetro. Aquí tienes una descripción general para crear un circuito PWM básico:

Componentes Necesarios:

- LM555 Timer IC

- Resistor (e.g. $R_1$ = 1kΩ, $R_2$ = 10kΩ)

- Capacitor (e.g. $C_1$ = 10nF, $C_2$ = 47nF)

- Potenciómetro (e.g. $RV_1$ = 100kΩ)

- Diodos (e.g. $D_1$, $D_2$, $D_3$ = 1N4007W)

-

Conecta $IC_1$ (555 Timer) conforme a lo siguiente:

- Pin 1 (GND) a GND

- Pin 2 (TRIG) a Pin 6 (THR)

- Pin 3 (OUT) a $PWM_OUT$:P1

- Pin 4 (RESET) a VCC

- Pin 5 (CTRL) mediante un capacitor $C_1$:P2 a GND

- Pin 6 (THR) mediante $D_2$:K al potenciómetro $RV_1$ terminal medio

- Pin 7 (DISCH) al nodo entre $R_1$ y $R_2$

- Pin 8 (VCC) a VCC

-

Conecta el potenciómetro $RV_1$:

- Un terminal lateral a VCC

- Terminal opuesto a GND

-

Conecta los resistores:

- $R_1$:P1 a VCC

- $R_1$:P2 al terminal medio del potenciómetro

- $R_2$:P1 al terminal medio del potenciómetro y $D_3$:A

- $R_2$:P2 al pin 7 del 555

-

Un capacitor de desacoplo $C_2$ entre VCC y GND para suavizar posibles fluctuaciones de voltaje.

Este circuito genera una señal PWM cuya frecuencia se determina por la combinación de los valores de resistores y el condensador, mientras que se puede ajustar el ciclo de trabajo usando el potenciómetro.

Por favor, indica si deseas algún ajuste específico en el diseño o si hay alguna otra consulta que pueda ayudarte.

1y

Someone is typing...

8

https://cdn2.flux.ai/flux-comment-files/files/commentFileId-1690907a8019ec0aa743...

@copilot https://cdn2.flux.ai/flux-comment-files/files/commentFileId-1690907a8019ec0aa7439829b3d53611fe95293cde173504fdbc6ecd1b4782aa.jpeg?GoogleAccessId=graviton-mvp%40appspot.gserviceaccount.com&Expires=4877702512&Signature=tSwMumVnRnjSDXe8Z3jddEMk2GIomL61XfmQrAqd3y%2B83j4pb%2BEotNRQUR3%2FkwR1gOMfDBQuLQQuOhmqRhjYiWxbeMTBloCocG4Ey5LWbL5UPMu5UWD0kjR7YudRauS6MRH1RKXA2pwW41iiDFrdAoLbVDZJ4g8w%2FYNCaahzGk0BlTR9A83u8bQyOnNyYaoheEsmogDGTTjjUUGDLwjm9%2B7%2F9HlzDmb79AaclpRq4oUodzAyvLXLzOQ%2B5Kdj4XmsiqclKQZrVor%2FJWsitM0HpjvWQTJtxJQwmD2iYSOmFZCrSMygioDyBhNA%2BDSZcWvvVc9V0EGl9u5Vty%2BzJCxdwQ%3D%3D

1y

It seems like you've uploaded an image, but there was no accompanying question or context. How can I assist you with your Pulse Width Modulation (PWM) Controller project? Are you looking for help with a specific component, connection, or troubleshooting within Flux?

1y

Someone is typing...

7

explain this project.

@copilot why there are two diodes connected to the potentiometer with different polarization

1y

The two diodes connected to the potentiometer (RV1) with differing polarization serve a specific function in the Pulse Width Modulation (PWM) Controller circuit, mainly related to shaping and controlling the charge and discharge paths within the circuit. Let's break down their role:

- D2 (1N4007W) connected with its cathode (K) to RV1, and D3 (1N4007W) connected with its anode (A) to RV1 create alternate paths for current flow during different phases of the operation of the LM555 timer IC in the circuit.

-

Charge Phase: During the charge phase, the output of the LM555 timer (IC1:Q) is high, allowing current to flow through the charge path. D3 (1N4007W) is polarized such that its anode (A) is connected to the discharge (DIS) pin of the LM555 (IC1:DIS) via the potentiometer RV1. This allows D3 to conduct during the charge phase, providing a path for the charge current to reach the timing capacitor (C2) via the potentiometer RV1. This configuration allows the charging time (and thus, the pulse width) to be adjustable via RV1.

-

Discharge Phase: Conversely, when IC1's output (Q) goes low, it initiates the discharge phase. The discharge pin (IC1:DIS) directly connects to the timing capacitor (C2). In this phase, D2 (with its cathode to RV1) becomes forward-biased, allowing the capacitor C2 to discharge through it and the potentiometer RV1. D3 is reverse-biased in this phase and does not conduct.

-

PWM Control via Potentiometer: The use of two diodes in this manner, with one facing each direction, effectively allows the potentiometer to adjust the charge and discharge times of the timing capacitor differently. This is useful for adjusting the duty cycle of the PWM signal.

-

Protection and Directionality: Besides adjustment, these diodes also ensure current flows in the correct direction during each phase, protecting other components and preventing undesired feedback.

-

Impedance Matching: It also plays a role in matching the impedance during the charge and discharge cycles, ensuring stable operation of the timer.

By having the diodes in reverse orientations relative to each other, the circuit can utilize the varying resistance of the potentiometer to effectively manipulate both the charge and discharge times, thereby adjusting the duty cycle of the PWM output. This is critical for applications requiring precise control over the PWM signal characteristics.

1y

2y

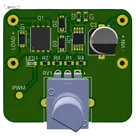

This project is a Pulse Width Modulation (PWM) Controller, which uses an LM555 timer IC as its main component. The design is constructed to control a load, such as a motor or LED, using a MOSFET (SIR680ADP-T1-RE3). The duty cycle of the PWM signal can be adjusted using a potentiometer (P0915N-FC15BR100K).

Here are the main parts of the controller:

-

LM555 timer (IC1): It is configured in the astable mode, which allows it to produce a PWM signal. The key pins are Ground (GND), Trigger (TR), Output (Q), Reset (R), Control Voltage (CV), Threshold (THR), Discharge (DIS), and Supply voltage (VCC).

-

MOSFET (Q1): This component allows the PWM signal from the LM555 to control a larger load.

-

Potentiometer (RV1): This adjustable resistor is used to modify the duty cycle of the PWM signal, thus changing the amount of time a signal is on versus off.

-

Resistors (R1, R2, R3, R4): These are used for various functions within the circuit such as current limiting and setting the oscillation frequency of the PWM signal.

-

Capacitors (C1, C2, C3): They have various functions such as smoothing out power supply noise, and, paired with resistors, setting the frequency and duty cycle of the PWM signal.

-

Diodes (D1, D2, D3): These direct current in only one direction, and prevent it from flowing in the opposite direction.

Without knowing the exact connections of individual pins, that is a general overview of how the PWM Controller should work.

2y

Someone is typing...

2

explain this project.

@copilot explain this project.

1y

This project describes the design and components of a Pulse Width Modulation (PWM) Controller using an LM555 timer IC. Pulse Width Modulation is a technique used to encode the amplitude of a signal into the width of a series of signal pulses, effectively controlling power delivery to various types of loads. This kind of controller can be used for various applications including motor control, dimming LED lights, or controlling the heat output of heating elements.

Key Components:

-

IC1 (LM555CM): Central to the project, the LM555 timer IC is used in a configuration that generates PWM signals. It has various pins for different functions like threshold (THR), trigger (TR), discharge (DIS), control voltage (CV), reset (R), output (Q), and power supply (VCC/GND).

-

Q1 (SIR680ADP-T1-RE3): A MOSFET used to drive the load with the PWM signal generated by IC1. It acts as a switch that controls the power supplied to the load.

-

RV1 (P0915N-FC15BR100K): A potentiometer used to adjust the PWM signal's duty cycle by altering the resistance in the circuit, thus controlling the effective power delivered to the load.

-

Capacitors (C1, C2, C3): Used for various purposes including filtering and timing. C1 and C2 are smaller (10nF and 47nF respectively), likely used for timing and noise reduction, while C3 is a larger capacitor (100uF) possibly for power supply smoothing.

-

Resistors (R1, R2, R3, R4): Used to set biasing currents, timing characteristics for the PWM, and possibly for pull-up/down configurations. R1 and R2 are 1kΩ, and R3 and R4 are 10kΩ.

-

LED1: Used as an indicator, likely showing the PWM controller's operational status or PWM signal presence.

-

Diodes (D1, D2, D3): Likely used for protecting the circuit from voltage spikes, directing current flow, or as part of a freewheeling diode arrangement. All three diodes are 1N4007W types, which are general-purpose, high-voltage rectifier diodes.

-

Multiple nets define how components are interconnected, ensuring the proper flow of electrical signals and power through the circuit. Notable nets include connections for the IC1's various pins (GND, TR, Q, R, CV, THR, DIS, VCC), which are crucial for its configuration and operation as a PWM generator.

-

The project involves various nets for interconnecting components like the potentiometer (RV1) for adjusting the PWM signal, the capacitor (C1, C2, C3) and resistor networks (R1, R2, R3, R4) for timing and signal shaping, the MOSFET (Q1) for driving the load, and diodes (D1, D2, D3) for protection.

-

The project uses various designators such as PWM_OUT, VIN, LOAD+, and LOAD- for easy identification of major connection points like the PWM signal output, power input, and load connections.

-

The use of the license (Creative Commons Attribution 4.0 International License) suggests that the design is open for modification and redistribution, encouraging community sharing and iteration on this basic PWM controller design.

Overall, this project represents a fundamental but versatile PWM Controller circuit, demonstrating the essential components and configurations used in PWM signal generation and application.

1y

Someone is typing...

4

please explain what IC1 does.

Someone is typing...

6

C2

Not Recommended for New Designs

Capacitance

47n F

PWM_OUT

C1

Capacitance

10n F

-Vin

+Vin

VIN

R3

Resistance

10k Ω

D3

C3

Capacitance

100u F

VIN

D2

VIN

IC1

9

https://cdn2.flux.ai/flux-comment-files/files/commentFileId-6bb69a7e732fb40a316f...

@copilot https://cdn2.flux.ai/flux-comment-files/files/commentFileId-6bb69a7e732fb40a316fd4ace7ec8132cf727430a687e1980e10697b920dff85.jpeg?GoogleAccessId=graviton-mvp%40appspot.gserviceaccount.com&Expires=4882170783&Signature=Xnw7PKuDqXjZoVCdhuSpjefIEp1ObWlV2MgdJHSGBHscbCbx1%2FpneE7u%2BhUU8sn8P6lbtNaK9biU5hVQTeRpeWRDJxfYo7I8oxCj4aO%2FH1bBsKTgkiE4JrmKp9GeD8%2FdpNh0SQ1EA%2FX58qKFD7ek5iK37nWL308EnreXoIMb%2F1eBVVgAJlIMeDUII%2F8eTHCnuTfjY%2BKy7bwcV89ordSHXAT0CVzpZJIx%2Bz32pnll2OIsEANHO2TF2c54XfWEt4futCKLzA7fTJOVInxU6NgkWYRdZ%2FT%2BGAhZF5TXKW%2FgNiWENkc1jPP9JOb0WcE564QWu5qs50i0eLHm1i2Y2%2Fq1Tg%3D%3D

1y

It looks like you have an enclosure with some rotary switches, LEDs, and what appears to be a display module and additional components. How can I assist you with your project?

1y

Someone is typing...

Reviews

Electrical Rule Checks

Missing Footprints

Reports components that need a footprint but don't have one.

Design Rule Checks

Overlapping Copper

Reports copper elements that are shorting.

Invalid Layer

Reports nodes that are assigned to a layer that doesn't exist in the layout stackup.

Component Overrides • 6

Airwires • 1

Designators | Net | |

|---|---|---|

Layers with Multiple Fills

Reports layers that have multiple copper fills of different nets. Make sure the Connected Layers rule value of nets with fills is valid.

Floating Copper

Detect any via, trace or copper fill island that is not connected to any net.

Protected Intrusions

Reports intrusions from objects of other nets into polygons or fills that have the Protected layout rule applied.

System Checks

Auto-Layout

BetaReports issues with Auto-Layout if Flux cannot route something or must ignore a configuration.

Passive Components

Decoupling Capacitors

BetaIC | ... | |

|---|---|---|

IC1:VCC |

Resistor Power Rating

BetaResistor | Margin | Calculated Power | ... | |

|---|---|---|---|---|

R1 | None | None | ||

R2 | None | None | ||

R3 | None | None | ||

R4 | None | None | ||

RV1 | None | None |

Pull Up/Pull Down

BetaChecks that IC pins that require pull up or pull down resistors have them.

Learn moreCapacitor Voltage Rating

BetaCapacitor | Headroom | ... | |

|---|---|---|---|

C1 | None | ||

C2 | None |

- Wirelessly connects nets on schematic. Used to organize schematics and separate functional blocks. To wirelessly connect net portals, give them same designator. #portaljharwinbarrozo43.0M

- Wirelessly connects power nets on schematic. Identical to the net portal, but with a power symbol. Used to organize schematics and separate functional blocks. To wirelessly connect power net portals, give them the same designator. #portal #powerjharwinbarrozo11.4M

- A generic fixed resistor for rapid developing circuit topology. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard resistor values: 1.0Ω 10Ω 100Ω 1.0kΩ 10kΩ 100kΩ 1.0MΩ 1.1Ω 11Ω 110Ω 1.1kΩ 11kΩ 110kΩ 1.1MΩ 1.2Ω 12Ω 120Ω 1.2kΩ 12kΩ 120kΩ 1.2MΩ 1.3Ω 13Ω 130Ω 1.3kΩ 13kΩ 130kΩ 1.3MΩ 1.5Ω 15Ω 150Ω 1.5kΩ 15kΩ 150kΩ 1.5MΩ 1.6Ω 16Ω 160Ω 1.6kΩ 16kΩ 160kΩ 1.6MΩ 1.8Ω 18Ω 180Ω 1.8KΩ 18kΩ 180kΩ 1.8MΩ 2.0Ω 20Ω 200Ω 2.0kΩ 20kΩ 200kΩ 2.0MΩ 2.2Ω 22Ω 220Ω 2.2kΩ 22kΩ 220kΩ 2.2MΩ 2.4Ω 24Ω 240Ω 2.4kΩ 24kΩ 240kΩ 2.4MΩ 2.7Ω 27Ω 270Ω 2.7kΩ 27kΩ 270kΩ 2.7MΩ 3.0Ω 30Ω 300Ω 3.0KΩ 30KΩ 300KΩ 3.0MΩ 3.3Ω 33Ω 330Ω 3.3kΩ 33kΩ 330kΩ 3.3MΩ 3.6Ω 36Ω 360Ω 3.6kΩ 36kΩ 360kΩ 3.6MΩ 3.9Ω 39Ω 390Ω 3.9kΩ 39kΩ 390kΩ 3.9MΩ 4.3Ω 43Ω 430Ω 4.3kΩ 43KΩ 430KΩ 4.3MΩ 4.7Ω 47Ω 470Ω 4.7kΩ 47kΩ 470kΩ 4.7MΩ 5.1Ω 51Ω 510Ω 5.1kΩ 51kΩ 510kΩ 5.1MΩ 5.6Ω 56Ω 560Ω 5.6kΩ 56kΩ 560kΩ 5.6MΩ 6.2Ω 62Ω 620Ω 6.2kΩ 62KΩ 620KΩ 6.2MΩ 6.8Ω 68Ω 680Ω 6.8kΩ 68kΩ 680kΩ 6.8MΩ 7.5Ω 75Ω 750Ω 7.5kΩ 75kΩ 750kΩ 7.5MΩ 8.2Ω 82Ω 820Ω 8.2kΩ 82kΩ 820kΩ 8.2MΩ 9.1Ω 91Ω 910Ω 9.1kΩ 91kΩ 910kΩ 9.1MΩ #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed capacitor ideal for rapid circuit topology development. You can choose between polarized and non-polarized types, its symbol and the footprint will automatically adapt based on your selection. Supported options include standard SMD sizes for ceramic capacitors (e.g., 0402, 0603, 0805), SMD sizes for aluminum electrolytic capacitors, and through-hole footprints for polarized capacitors. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard capacitor values: 1.0pF 10pF 100pF 1000pF 0.01uF 0.1uF 1.0uF 10uF 100uF 1000uF 10,000uF 1.1pF 11pF 110pF 1100pF 1.2pF 12pF 120pF 1200pF 1.3pF 13pF 130pF 1300pF 1.5pF 15pF 150pF 1500pF 0.015uF 0.15uF 1.5uF 15uF 150uF 1500uF 1.6pF 16pF 160pF 1600pF 1.8pF 18pF 180pF 1800pF 2.0pF 20pF 200pF 2000pF 2.2pF 22pF 20pF 2200pF 0.022uF 0.22uF 2.2uF 22uF 220uF 2200uF 2.4pF 24pF 240pF 2400pF 2.7pF 27pF 270pF 2700pF 3.0pF 30pF 300pF 3000pF 3.3pF 33pF 330pF 3300pF 0.033uF 0.33uF 3.3uF 33uF 330uF 3300uF 3.6pF 36pF 360pF 3600pF 3.9pF 39pF 390pF 3900pF 4.3pF 43pF 430pF 4300pF 4.7pF 47pF 470pF 4700pF 0.047uF 0.47uF 4.7uF 47uF 470uF 4700uF 5.1pF 51pF 510pF 5100pF 5.6pF 56pF 560pF 5600pF 6.2pF 62pF 620pF 6200pF 6.8pF 68pF 680pF 6800pF 0.068uF 0.68uF 6.8uF 68uF 680uF 6800uF 7.5pF 75pF 750pF 7500pF 8.2pF 82pF 820pF 8200pF 9.1pF 91pF 910pF 9100pF #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed inductor for rapid developing circuit topology. *You can now change the footprint and 3D model at the top level anytime you want. This is the power of #genericsjharwinbarrozo15.1k

- An electrical connector acting as reusable interface to a conductor and creating a point where external circuits can be connected.Terminal

- 47 kOhms ±5% 0.125W, 1/8W Chip Resistor 0805 (2012 Metric) Automotive AEC-Q200 Thick Film #forLedBlinkjharwinbarrozo1.2M

- 10uF Capacitor Aluminum Polymer 20% 16V SMD 5x5.3mm #forLedBlink #commonpartslibrary #capacitor #aluminumpolymer #radialcanjharwinbarrozo1.2M

- Yellow 595nm LED Indication - Discrete 1.7V 1206 (3216 Metric) #forLedBlinkjharwinbarrozo1.1M

Inspect

Pulse Width Modulation (PWM) Controller

Controls

Properties

Availability & Pricing

| Distributor | Qty 1 | |

|---|---|---|

| Digi-Key | $3.47–$4.48 | |

| LCSC | $2.43–$2.80 | |

| Mouser | $6.00 | |

Assets

- Pulse Width Modulation (PWM) Controller-removebg-preview.png

id=Pulse Width Modulation (PWM) Controller-removebg-preview

Thumbnail

Welcome 👋

Flux helps you build PCBs faster with an AI teammate!

Create your account to collaborate, stay updated, fork your own version, and get instant answers from our AI agent.

valikxd

copilot