Chat

Welcome to Flux

Treat Flux like your intern. Tell it what you'd like to build and it'll get to work. You can also ask it questions, brainstorm ideas, and teach it your preferences. Learn More

Explain project

Write a project description

Find schematic issues

Create a test plan

Simulate a circuit

Ready.

do all of my ICs (U1, U2, U3, U4, IC1, IC2) meet or exceed the project operating...

2y

To answer your question, I will evaluate each of the Integrated Circuits (ICs) listed in your project against the specified operating temperature range of -10°C to 70°C.

-

U1: RT8059GJ5

The RT8059GJ5 has an operating junction temperature range of 40°C to 125°C[1]. Since this is a junction temperature range, the ambient temperature at which this IC can safely operate is generally lower. The maximum ambient temperature is specified as 85°C[1]. This means that U1 exceeds the project’s operating temperature range requirement. -

U2: CN3063

The CN3063 has an operating temperature range of -40°C to 85°C[2]. This range more than covers the project's required operating temperature range of -10°C to 70°C. So, U2 also meets the project requirements. -

U3: SY6280AAAC

The SY6280AAAC’s ambient operating temperature range is specified as -40°C to 85°C[3], which comfortably exceeds the requirement for this project. -

U4: 317990687

For the LoRa-E5 module (317990687), the operating ambient temperature range is -40°C to 85°C[4], which matches the project's requirement. -

IC1: MT3608L

The MT3608L has an operating temperature range of -40°C to 85°C[5], which means it also exceeds the project's operating temperature range. -

IC2: SP3485EN-L/TR

For the SP3485EN-L/TR, the specified operating temperature range is -40°C to +85°C[6], which meets and exceeds the project's requirements.

In summary, all of your listed Integrated Circuits (U1, U2, U3, U4, IC1, IC2) comfortably meet or exceed the project's operating temperature range of -10°C to 70°C.

[1] Page 3

[2] Page 4

[3] Page 2

[4] Page 5

[5] Page 2

[6] Page 9

2y

Someone is typing...

1

are there any issues in this project?

2y

After reviewing the "Green Dot 2040E5" Board project, here are a few potential issues I've identified, based on common design considerations for IoT and power management in schematics:

-

Power Management and Decoupling Capacitors:

- Ensuring proper decoupling and filtering might require reviewing the placements and values of the capacitors near power-consuming ICs, such as U6 (XIAO RP2040), U3 (Silergy Corp SY6280AAAC), and U1 (RT8059GJ5).

-

Solar Charging Circuit:

- The project mentions solar charging capabilities, but specific details about the solar panel, its voltage, current characteristics, and connection to the charging circuit (possibly involving U2, CN3063) need to be clear. Ensure the circuit design matches the solar panel's output characteristics for efficient charging.

-

Battery Protection:

- With U2 (CN3063) being part of the power management indicating charging capabilities, ensuring there are appropriate battery protection mechanisms (over-charge, over-discharge, short-circuit protection) is critical. Some of these functions may be built into U2, but this should be confirmed.

-

RS485 Communication:

- IC2 (SP3485EN-L/TR) handles RS485 communication. Ensure proper termination resistors are used, and the communication lines to the microcontroller (U6, XIAO RP2040) are correctly connected and protected against transients.

-

IoT Connectivity Using LoRa:

- U4 should be connected correctly for LoRa communication, including its interface with U6 for SPI communication and control lines. Also, make sure the antenna design is compatible with the module's requirements for optimal range.

-

Ambient Conditions and Operating Range:

- Given the operating temperature range is mentioned (-10°C to 70°C), ensure all components selected can operate within these limits. Particularly, check the specifications of critical components like the MCU (U6), LoRa module (U4), and any sensors interfaced with the board.

-

Power Supply Concerns:

- Confirm that the power supply design can consistently deliver the required voltages and currents under all operating conditions. For solar-powered devices, consider the power budget throughout the day and under different weather conditions.

- Ensure there's clear management of the multiple voltage levels mentioned (VIN, 3.3V, and potentially 5V from USB), including how they are sourced and switched.

-

Compliance and Testing:

- Given the RoHS compliance requirement, make sure all components meet these standards.

- For manufacturing, especially with a quantity target of 10,000, ensuring the design is conducive to testing (e.g., test points, programming interfaces) will be important for quality control.

-

General Design and Layout Observations:

- Ensure that all nets are correctly connected, and there are no unconnected pins or nets that are critical for operation.

- Confirm that all component footprints match the actual components selected (especially for SMD parts) and that polarity markings are clear for components like diodes and capacitors.

Without specific design details or error reports related to connections, routing, or component specifications, these are general recommendations. It's advisable to simulate critical aspects of the circuit, review the datasheets for components carefully, especially for power management ICs, and check the layout to minimize issues with noise, signal integrity, and power distribution.

2y

Someone is typing...

6

Check that all reset/enable have an external pull-up or pull-down resistors. Rep...

1y

To ensure proper operation of the components in the "Green Dot 2040E5" board, it's essential to verify that all reset and enable lines are correctly configured with either pull-up or pull-down resistors as required by their respective datasheets. Here are the action items to address this concern:

-

U6 (XIAO RP2040) - RUN Pin:

- Action: Check for external pull-up on RUN pin.

- This is required for resetting the chip. If not utilized, it should be tied high[1]. This suggests the need for an external pull-up resistor if the RUN pin is utilized for reset purposes.

-

U4 (LoRa-E5 STM32WLE5JC) - NRST Pin:

- Action: Ensure there is an external pull-up or pull-down on NRST (Pin 17).

- It’s typically best practice to have an external pull-up on the NRST pin for microcontrollers to ensure a defined level on power-up or external reset conditions. The datasheet excerpt did not directly mention the need for a pull-up/down for NRST; however, external manipulation of this pin for reset purposes usually requires an external resistor to define its state securely.

-

U3 (SY6280AAAC) - EN Pin:

- Action: Verify an external pull-up resistor is connected to the EN pin (Pin 4) to ensure the IC is enabled when required[2]. It is indicated that this pin should not be left floating and must be pulled high to enable the IC.

-

IC1 (MT3608L) - EN Pin:

- Action: Conclude if an external resistor is needed based on the specific behavior desired at the EN pin. Normally, DC-DC converters like MT3608 require pulling the EN pin to a defined logic level to control the enable/disable state. Since explicit information isn't provided in the excerpts, a general practice is to use a pull-up resistor to keep the converter active unless explicitly disabled by a connected GPIO.

-

U1 (RT8059GJ5) - EN Pin:

- Action: Similar to IC1, decide on utilizing an external pull-up resistor on the EN pin to ensure the device is enabled as intended or if specific enable/disable control is required through GPIO.

-

U2 (CN3063) - Not specified for reset or enable control

- Note: Although there's no direct mention of a reset or enable pin in the excerpts provided for the CN3063, it's essential to consult the full datasheet to determine if any external resistors are necessary for operational stability.

For action items related to components where direct information isn't provided in the excerpts or specifications imply general electronics principles not covered in the excerpts, it's advisable to consult the full datasheets or manufacturer guidelines for clarity. Furthermore, reviewing the existing schematic would be essential to confirm the presence or absence of these resistors.

[1] Page 152

[2] Page 2

1y

Someone is typing...

8

Check that none of the unconnected pins require pull-up or pull-down resistors t...

1y

To assess whether any unconnected pins in your project require pull-up or pull-down resistors for proper function, we will go through each component with unconnected pins based on the provided schematic details and assess common requirements for similar components based on typical datasheets and design practices.

XIAO RP2040 (U6)

- Unconnected Pins: Guidance largely depends on the specific use of each GPIO. The XIAO RP2040 datasheet and hardware design guidelines usually recommend specific configurations for unused GPIOs, typically suggesting that they be left floating or configured as inputs with software pull-ups/pull-downs as needed. However, for critical applications or pins with specific functions (e.g., boot configuration pins), external pull resistors might be necessary. For the general-purpose IO pins listed, no specific pull-up or pull-down resistors are mentioned here, but it's wise to refer to the specific guidelines from Seeed Studio or RP2040 datasheets.

- Unconnected Pins: Most communication modules, including LoRa modules, are typically designed to be tolerant of floating pins that are not used in a particular application, especially for GPIO or peripheral function pins. Ensure that the SPI, I2C, UART, or other interface lines used are correctly terminated according to the module's datasheet. The unconnected pins in this description typically don't require pull-up or pull-down resistors unless specified for particular configurations (e.g., for boot mode or reset functions).

- Unconnected Pins: The Transmit Enable (DE) and Receiver Enable (~RE~) pins are connected together to form an 'ENABLE' net, which suggests they are intentionally controlled for RS485 half-duplex operation. Unconnected pins, such as those not mentioned here, would typically not require pull-up or pull-down resistors unless specifically recommended by the datasheet.

- Digital Input Pins: Should generally have either pull-up or pull-down resistors to ensure they do not float if unconnected. This includes configuration pins, select pins, or mode pins not explicitly mentioned in your project description.

- Analog Pins: If not used, analog pins are typically left unconnected but refer to the component's datasheet as some may recommend connecting unused analog inputs to ground through a resistor.

- Power Enable or Chip Select Pins: These are commonly seen in ICs requiring active high or low signals to operate or standby. Unconnected pins assumed to be power enable or chip select should typically be pulled to the appropriate logic level to ensure the correct default state.

- Output Pins: Generally do not require pull-up or pull-down resistors unless they are open-drain or open-collector outputs that require external resistors to define the logic high state.

For this project, based on the components listed and typical practices:

- Most unconnected pins will not require pull-up or pull-down resistors unless specified by the component datasheet for proper operation or to set a default state.

- It's crucial to review each component's datasheet individually for recommendations on handling unconnected pins, especially for microcontrollers, transceivers, and sensors.

If specific datasheets or component guidelines suggest the addition of pull-up or pull-down resistors for unconnected pins and those details haven't been provided here, please consult those documents directly or let me know if you have particular concerns about specific pins or components.

1y

Someone is typing...

9

VUSB

R11

Resistance

22 Ω

R14

Resistance

120 Ω

+3V3

PIO2

A

SCL

+3V3

SW2

U4

+3V3

R17

Resistance

4k7 Ω

NRST

R13

Resistance

470 Ω

B

RX

NRST

SDA

PIO1

DI

ENABLE

C12

Capacitance

100n F

12_5V

J6

H2

H1

R18

Resistance

22 Ω

RO

+3V3

IC2

U6

Reviews

Electrical Rule Checks

Duplicate Designators

Reports components with identical designators.

No-Connect Violation

Reports no-connect pins that are connected.

Pin-to-Pin Conflicts

Reports incompatible pin connections on the same net based on electrical pin types.

Shorted Components

Reports any 2-pin component with both pins connected to the same net.

Missing Power

Reports power input pins that are not connected to a power source.

Single Pin Nets

Reports nets that have only one pin connected.

Missing Designator

Reports components without a designator.

Design Rule Checks

Overlapping Copper

Reports copper elements that are shorting.

Invalid Layer

Reports nodes that are assigned to a layer that doesn't exist in the layout stackup.

Component Overrides

Reports components that have been modified using the "!important" flag.

Airwires

Reports missing routed traces between pads in a net.

Layers with Multiple Fills

Reports layers that have multiple copper fills of different nets. Make sure the Connected Layers rule value of nets with fills is valid.

Floating Copper

Detect any via, trace or copper fill island that is not connected to any net.

Protected Intrusions

Reports intrusions from objects of other nets into polygons or fills that have the Protected layout rule applied.

Missing Footprints

Reports components that need a footprint but don't have one.

Manufacturing

Manufacturer Part Number

Reports components that have no manufacturer part number.

Parts Available

BetaChecks that all components are available from distributors.

System Checks

Auto-Layout

BetaReports issues with Auto-Layout if Flux cannot route something or must ignore a configuration.

Passive Components

Resistor Power Rating

BetaChecks that the power traveling across a given resistor is under its rating with 50% headroom.

Learn morePull Up/Pull Down Presence

BetaChecks that IC pins that require pull up or pull down resistors have them.

Learn moreCapacitor Voltage Rating

BetaChecks that capacitors have appropriate voltage ratings to prevent overheating and ensure reliable circuit operation.

- Wirelessly connects nets on schematic. Used to organize schematics and separate functional blocks. To wirelessly connect net portals, give them same designator. #portaljharwinbarrozo43.0M

- Wirelessly connects power nets on schematic. Identical to the net portal, but with a power symbol. Used to organize schematics and separate functional blocks. To wirelessly connect power net portals, give them the same designator. #portal #powerjharwinbarrozo11.4M

- A generic fixed resistor for rapid developing circuit topology. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard resistor values: 1.0Ω 10Ω 100Ω 1.0kΩ 10kΩ 100kΩ 1.0MΩ 1.1Ω 11Ω 110Ω 1.1kΩ 11kΩ 110kΩ 1.1MΩ 1.2Ω 12Ω 120Ω 1.2kΩ 12kΩ 120kΩ 1.2MΩ 1.3Ω 13Ω 130Ω 1.3kΩ 13kΩ 130kΩ 1.3MΩ 1.5Ω 15Ω 150Ω 1.5kΩ 15kΩ 150kΩ 1.5MΩ 1.6Ω 16Ω 160Ω 1.6kΩ 16kΩ 160kΩ 1.6MΩ 1.8Ω 18Ω 180Ω 1.8KΩ 18kΩ 180kΩ 1.8MΩ 2.0Ω 20Ω 200Ω 2.0kΩ 20kΩ 200kΩ 2.0MΩ 2.2Ω 22Ω 220Ω 2.2kΩ 22kΩ 220kΩ 2.2MΩ 2.4Ω 24Ω 240Ω 2.4kΩ 24kΩ 240kΩ 2.4MΩ 2.7Ω 27Ω 270Ω 2.7kΩ 27kΩ 270kΩ 2.7MΩ 3.0Ω 30Ω 300Ω 3.0KΩ 30KΩ 300KΩ 3.0MΩ 3.3Ω 33Ω 330Ω 3.3kΩ 33kΩ 330kΩ 3.3MΩ 3.6Ω 36Ω 360Ω 3.6kΩ 36kΩ 360kΩ 3.6MΩ 3.9Ω 39Ω 390Ω 3.9kΩ 39kΩ 390kΩ 3.9MΩ 4.3Ω 43Ω 430Ω 4.3kΩ 43KΩ 430KΩ 4.3MΩ 4.7Ω 47Ω 470Ω 4.7kΩ 47kΩ 470kΩ 4.7MΩ 5.1Ω 51Ω 510Ω 5.1kΩ 51kΩ 510kΩ 5.1MΩ 5.6Ω 56Ω 560Ω 5.6kΩ 56kΩ 560kΩ 5.6MΩ 6.2Ω 62Ω 620Ω 6.2kΩ 62KΩ 620KΩ 6.2MΩ 6.8Ω 68Ω 680Ω 6.8kΩ 68kΩ 680kΩ 6.8MΩ 7.5Ω 75Ω 750Ω 7.5kΩ 75kΩ 750kΩ 7.5MΩ 8.2Ω 82Ω 820Ω 8.2kΩ 82kΩ 820kΩ 8.2MΩ 9.1Ω 91Ω 910Ω 9.1kΩ 91kΩ 910kΩ 9.1MΩ #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed capacitor ideal for rapid circuit topology development. You can choose between polarized and non-polarized types, its symbol and the footprint will automatically adapt based on your selection. Supported options include standard SMD sizes for ceramic capacitors (e.g., 0402, 0603, 0805), SMD sizes for aluminum electrolytic capacitors, and through-hole footprints for polarized capacitors. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard capacitor values: 1.0pF 10pF 100pF 1000pF 0.01uF 0.1uF 1.0uF 10uF 100uF 1000uF 10,000uF 1.1pF 11pF 110pF 1100pF 1.2pF 12pF 120pF 1200pF 1.3pF 13pF 130pF 1300pF 1.5pF 15pF 150pF 1500pF 0.015uF 0.15uF 1.5uF 15uF 150uF 1500uF 1.6pF 16pF 160pF 1600pF 1.8pF 18pF 180pF 1800pF 2.0pF 20pF 200pF 2000pF 2.2pF 22pF 20pF 2200pF 0.022uF 0.22uF 2.2uF 22uF 220uF 2200uF 2.4pF 24pF 240pF 2400pF 2.7pF 27pF 270pF 2700pF 3.0pF 30pF 300pF 3000pF 3.3pF 33pF 330pF 3300pF 0.033uF 0.33uF 3.3uF 33uF 330uF 3300uF 3.6pF 36pF 360pF 3600pF 3.9pF 39pF 390pF 3900pF 4.3pF 43pF 430pF 4300pF 4.7pF 47pF 470pF 4700pF 0.047uF 0.47uF 4.7uF 47uF 470uF 4700uF 5.1pF 51pF 510pF 5100pF 5.6pF 56pF 560pF 5600pF 6.2pF 62pF 620pF 6200pF 6.8pF 68pF 680pF 6800pF 0.068uF 0.68uF 6.8uF 68uF 680uF 6800uF 7.5pF 75pF 750pF 7500pF 8.2pF 82pF 820pF 8200pF 9.1pF 91pF 910pF 9100pF #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed inductor for rapid developing circuit topology. *You can now change the footprint and 3D model at the top level anytime you want. This is the power of #genericsjharwinbarrozo15.4k

- An electrical connector acting as reusable interface to a conductor and creating a point where external circuits can be connected.Terminal

- 47 kOhms ±5% 0.125W, 1/8W Chip Resistor 0805 (2012 Metric) Automotive AEC-Q200 Thick Film #forLedBlinkjharwinbarrozo1.2M

- 10uF Capacitor Aluminum Polymer 20% 16V SMD 5x5.3mm #forLedBlink #commonpartslibrary #capacitor #aluminumpolymer #radialcanjharwinbarrozo1.2M

- Yellow 595nm LED Indication - Discrete 1.7V 1206 (3216 Metric) #forLedBlinkjharwinbarrozo1.1M

Inspect

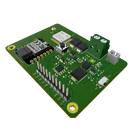

The Green Dot 2040E5 Board

Controls

Properties

Compliance

RoHS

Operating Voltage

12.5V

Operating Temperature

-10°C to 70°C

Reliability Target (MTBF)

30000 hours

Domain

IoT

Manufacturing Quantity Target

10000

Availability & Pricing

| Distributor | Qty 1 | |

|---|---|---|

| Digi-Key | $15.88–$16.36 | |

| LCSC | $11.54–$12.46 | |

| Mouser | $15.58–$15.83 | |

Assets

- flux logo.svg

id=flux logo

- image-removebg.png

id=image-removebg

Default

Thumbnail

Welcome 👋

Flux helps you build PCBs faster with an AI teammate!

Create your account to collaborate, stay updated, fork your own version, and get instant answers from our AI agent.

kerry

copilot

Table