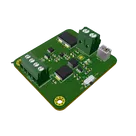

Project Overview: Power Management Board

2:08

General

Project

Here’s a concise, engineer’s walkthrough of your “BRAVE POWER MANAGEMENT BOARD.”

Purpose and system overview

- Goal: Provide regulated 12 V, 5 V, and 3.3 V rails for IoT systems from multiple sources: Li-ion battery, solar panel, or USB. Also recharge the battery from solar or USB.

- Primary functions:

- Battery charging from solar or USB.

- Boost conversion from battery to a higher rail (12/5 V).

- Load switching and 3.3 V regulation for logic/MCUs.

- Status indication and simple voltage sensing.

Core components and roles

-

Solar input and protection:

-

USB input:

-

Battery charger:

-

Battery connection:

-

Boost converter (12/5 V rail generation):

-

3.3 V rail and load switch:

- U1 is a synchronous buck/boost-like naming, but in this schematic it is wired as a regulator using LX, L2, and feedback network R3, R7, C8, producing 3V3. Input is VBAT.

- U3 high-side power switch gates the +3.3 V rail: VIN and EN controlled locally, output is 3V3 with output caps C5, C6. R5 to Net 2 sets current limit/soft-start depending on variant.

-

Outputs and connectors:

-

Sensing and indicators:

How the pieces interact

- Power path: Solar and USB are diode-ORed to the charger input. The charger manages battery charging and exposes status. VBAT feeds two downstream paths:

- Boost to 12/5 V via MT3608 (selectable via SW1 and divider), exported at J2.

- Regulate/switch to 3.3 V via RT8059 + SY6280 to power logic loads and provide a clean +3V3 at J2.

- Control and telemetry: EN pins on U1 and U3 plus sense dividers give simple hooks for MCU control/monitoring.

Design choices, trade-offs, and optimizations

-

Diode OR-ing for input selection:

- Pros: Simple, robust, no control logic needed, solar-friendly.

- Cons: Efficiency loss from Schottky forward drop (SS34) especially at higher current; reduces available charge headroom for solar.

-

MT3608 for 12/5 V:

- Pros: Widely available boost, compact, adequate for IoT loads. SW1 allows quick field selection between 12 V and 5 V profiles.

- Cons: If loads are heavy at 12 V, input current from VBAT rises quickly; careful inductor/diode/cap selection and thermal design required. Efficiency varies significantly between 5 V vs 12 V settings and load.

-

Separate 3.3 V path with high-side switch:

- Pros: The U3 isolates +3.3 V rail, supports controlled inrush and current limiting to protect the battery and system.

- Cons: Additional drop and quiescent consumption versus a bare LDO/switcher straight to the load.

-

Charger choice (CN3063):

- Pros: Tailored for solar (MPPT-like behavior via VIN regulation on some variants), common topology, status pins for UX.

- Cons: If true MPPT or dynamic power tracking is desired under varying irradiance, a dedicated solar PMIC might outperform a simple linear/switch charger with fixed ISET.

-

Feedback configurability:

- The use of SPDT + feedback networks provides flexibility between 12 V and 5 V use cases without rework.

Key technologies and dependencies

- Switching power conversion (boost and buck/step-down with inductor, diode, LX node).

- Input power OR-ing with Schottky diodes.

- Battery charging IC with programmable current and status signaling.

- High-side load switch for 3.3 V rail management.

- Standard passives (0603 caps/resistors), SWPA power inductors, through-hole terminal for field wiring.

Performance considerations and challenges

-

Thermal and efficiency:

- At 12 V output, ensure MT3608 inductor L1 current rating and D4 thermal dissipation are adequate. Output caps C10 should be low ESR and appropriately rated.

- For +3.3 V, verify the RT8059 switching frequency, inductor L2 saturation current, and compensation (R3/R7/C8) for stability across VBAT range.

-

Input headroom:

- Schottky drops on solar/USB reduce effective input to the charger; with weak sun or long cables, charging might not start or may be slow.

-

Start-up and inrush:

- Enabling +3.3 V or a heavy 12/5 V load can cause dips. The SY6280’s ISET and soft-start help; still consider sequencing and bulk capacitance.

-

EMI/layout:

-

Battery safety:

- Ensure charger parameters (ISET via R8) match the battery’s recommended charge current and that thermal regulation is acceptable in enclosure conditions.

Real-world applications

- Remote sensors, data loggers, and IoT gateways powered by small solar panels and Li-ion cells.

- Prototyping boards needing flexible 12 V/5 V plus a clean 3.3 V rail.

- Educational and lab setups to demonstrate multi-source power management.

Areas for improvement and future enhancements

-

Improve input selection efficiency:

- Replace diode-OR with an ideal diode controller or power mux to remove Schottky losses while preserving reverse blocking.

-

Smarter solar harvesting:

- Use a solar-optimized PMIC with true MPPT or programmable VIN regulation for better energy yield in partial shade/temperature variation.

-

Telemetry and protection:

-

Output configuration:

- If both 12 V and 5 V are needed simultaneously, consider a dedicated 12 V boost followed by a synchronous buck to 5 V, or two parallel converters from VBAT.

-

Efficiency tuning:

-

Control/UX:

-

Safety and compliance:

- Add fusing (polyfuse) on inputs and battery line, and evaluate creepage/clearance where applicable.

Scalability considerations

- Current scaling: For higher loads, move to synchronous boost/buck regulators with higher efficiency and thermal headroom.

- Modularization: Break out submodules (charger, 12/5 V, 3.3 V switch) as stackable or swappable modules to tailor to application needs.

- Manufacturability: Standardize on common footprints, ensure parts are active and multi-sourced; consider DFM: component clearances, test points on VBAT, +3V3, 12/5 V, and GND.

If you’d like, I can review DRC/ERC findings, check component values versus datasheets, or propose concrete parts for L1/L2/Cx and ISET based on your target loads and battery.

75 days

Ready.

can you help me add to my schematic dusk to dawn 5v out using mosfet and npn

Someone is typing...

how can i connect u1 and u4

Someone is typing...

8

Iset = 6800 / Rset

Iset = 6800 / 6.8k

Iset = 1A

Someone is typing...

3

Generate a markdown-formatted table to compare D5, D2. Highlight the main differ...

Someone is typing...

10

using the correct mermaid syntax, create a high level mermaid block diagram of t...

Someone is typing...

5

explain this project.

Someone is typing...

17

explain this project.

Someone is typing...

17

using current configurations, what is the charging current?

Someone is typing...

9

create a high level mermaid block diagram of IC1. Include key component's manufa...

Someone is typing...

28

please explain what U4 does.

Someone is typing...

22

create a detailed step by step plan table for this project to verify its functio...

Someone is typing...

12

list all R6 pins in a table format. For each pin provide its pin number, pin nam...

Someone is typing...

27

what's is ic1

Someone is typing...

25

C10? PART NO

Someone is typing...

30

WHAT IS THIS PROJECG ABOUT

Someone is typing...

21

Outline the electrical characteristics of U4 as detailed in the datasheet. Then,...

Someone is typing...

15

Perform an Electrical Rule Check (ERC) on the schematic for all the ICs, specifi...

Someone is typing...

7

create a high level mermaid block diagram of R7. Include key component's manufac...

Someone is typing...

13

create a high level mermaid block diagram of this project. Include key component...

Someone is typing...

4

, please perform a Design for Testability (DFT) review on the current schematic....

Someone is typing...

6

how do I change 12v out from boost to 5v

Someone is typing...

26

I\_ch = (V\_set / R\_set) x 900

I\_ch = (2 / 2k) x 900

I\_ch = 900mA

Someone is typing...

2

burada neden 10uH kullanılmış

Someone is typing...

14

explain this project.

Someone is typing...

16

MOUNTINT HOLE DIMENTIONS

Someone is typing...

31

Please validate the component ratings against the specified design parameters. T...

Someone is typing...

11

please explain what L1 does.

Someone is typing...

20

explain this project.

Someone is typing...

17

J3

C1

Capacitance

10u F

R9

Resistance

20k Ω

R8

Resistance

2k Ω

U3

Manufacturer Part Number

SY6280A AC

R7

Resistance

15k Ω

R6

Resistance

150k Ω

U1

Manufacturer Part Number

RT8059GJ5

C4

Capacitance

4u7 F

R1

Resistance

3k Ω

IC1

C2

Capacitance

10u F

U4

C3

Capacitance

100n F

R2

Resistance

1k5 Ω

C8

Capacitance

68p F

R4

Resistance

4k7

Ω

C10

Capacitance

22u F

C9

Capacitance

100n F

R3

Resistance

68k Ω

C7

Capacitance

22u F

R5

Resistance

6k8 Ω

C6

Capacitance

100n F

C5

Capacitance

10u F

L1

Inductance

10u H

SETTING OUTPUT VOLTAGE

Line 1

------------------------------------------------------------

Line 2

The internal reference VREF is typically 0.6V.

The output voltage is divided by a resistor divider,R1 and R2 to the FB pin.

Line 3

Vout = Vref x (1 + R6/R9)

Line 4

------------------------- AND ---------------------------

Line 5

Vout = Vref x (1 + R6/(R1+R4))

D1

VSOLAR

VUSB

VBAT

J1

+3V3

D4

D5

Color

Red

VBAT

SW1

D2

Color

Green

J4

+3V3

VBAT

VSOLAR

D3

VUSB

L2

Inductance

2u2 H

J2

12_5V

Reviews

Electrical Rule Checks

Missing Footprints

Reports parts that have no footprint.

Design Rule Checks

Overlapping Copper

Reports copper elements that are shorting.

Invalid Layer

Reports nodes that are assigned to a layer that doesn't exist in the layout stackup.

Component Overrides • 30

Designator | Ruleset | |

|---|---|---|

Airwires

Reports missing routed traces between pads in a net.

Deprecated Rules

Reports nodes that are using rules that are not supported anymore.

Layers with Multiple Fills

Reports layers that have multiple copper fills of different nets. Make sure the Connected Layers rule value of nets with fills is valid.

Floating Copper

Detect any via, trace or copper fill island that is not connected to any net.

Protected Intrusions

Reports intrusions from objects of other nets into polygons or fills that have the Protected layout rule applied.

Manufacturing

Manufacturer Part Number

Reports parts that have no manufacturer part number.

Parts Available

BetaDesignator | Stock | ... | |

|---|---|---|---|

C10 | None | ||

U3 | None | ||

C1 | 1M | ||

C2 | 1M | ||

C3 | 5M | ||

C4 | 107k | ||

C5 | 1M | ||

C6 | 5M | ||

C7 | 5M | ||

C8 | 105k | ||

C9 | 5M | ||

D1 | 7k | ||

D2 | 290k | ||

D3 | 7k | ||

D4 | 7k | ||

D5 | 2M | ||

IC1 | 271k | ||

J1 | 75k | ||

J2 | 9k | ||

J3 | 194k | ||

J4 | 54k | ||

L1 | 12k | ||

L2 | 31k | ||

R1 | 2M | ||

R2 | 2M | ||

R3 | 1M | ||

R4 | 2M | ||

R5 | 1M | ||

R6 | 1M | ||

R7 | 493k | ||

R8 | 1M | ||

R9 | 3M | ||

SW1 | 35k | ||

U1 | 65k | ||

U4 | 1k |

System Checks

Auto-Layout

BetaReports issues with Auto-Layout if Flux cannot route something or must ignore a configuration.

Passive Components

Resistor Power Rating

BetaChecks that the power traveling across a given resistor is under its rating with 50% headroom.

Learn morePull Up/Pull Down Presence

BetaChecks that IC pins that require pull up or pull down resistors have them.

Learn moreCapacitor Voltage Rating

BetaChecks that capacitors have appropriate voltage ratings to prevent overheating and ensure reliable circuit operation.

- Wirelessly connects nets on schematic. Used to organize schematics and separate functional blocks. To wirelessly connect net portals, give them same designator. #portaljharwinbarrozo43.0M

- Wirelessly connects power nets on schematic. Identical to the net portal, but with a power symbol. Used to organize schematics and separate functional blocks. To wirelessly connect power net portals, give them the same designator. #portal #powerjharwinbarrozo11.4M

- A generic fixed resistor for rapid developing circuit topology. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard resistor values: 1.0Ω 10Ω 100Ω 1.0kΩ 10kΩ 100kΩ 1.0MΩ 1.1Ω 11Ω 110Ω 1.1kΩ 11kΩ 110kΩ 1.1MΩ 1.2Ω 12Ω 120Ω 1.2kΩ 12kΩ 120kΩ 1.2MΩ 1.3Ω 13Ω 130Ω 1.3kΩ 13kΩ 130kΩ 1.3MΩ 1.5Ω 15Ω 150Ω 1.5kΩ 15kΩ 150kΩ 1.5MΩ 1.6Ω 16Ω 160Ω 1.6kΩ 16kΩ 160kΩ 1.6MΩ 1.8Ω 18Ω 180Ω 1.8KΩ 18kΩ 180kΩ 1.8MΩ 2.0Ω 20Ω 200Ω 2.0kΩ 20kΩ 200kΩ 2.0MΩ 2.2Ω 22Ω 220Ω 2.2kΩ 22kΩ 220kΩ 2.2MΩ 2.4Ω 24Ω 240Ω 2.4kΩ 24kΩ 240kΩ 2.4MΩ 2.7Ω 27Ω 270Ω 2.7kΩ 27kΩ 270kΩ 2.7MΩ 3.0Ω 30Ω 300Ω 3.0KΩ 30KΩ 300KΩ 3.0MΩ 3.3Ω 33Ω 330Ω 3.3kΩ 33kΩ 330kΩ 3.3MΩ 3.6Ω 36Ω 360Ω 3.6kΩ 36kΩ 360kΩ 3.6MΩ 3.9Ω 39Ω 390Ω 3.9kΩ 39kΩ 390kΩ 3.9MΩ 4.3Ω 43Ω 430Ω 4.3kΩ 43KΩ 430KΩ 4.3MΩ 4.7Ω 47Ω 470Ω 4.7kΩ 47kΩ 470kΩ 4.7MΩ 5.1Ω 51Ω 510Ω 5.1kΩ 51kΩ 510kΩ 5.1MΩ 5.6Ω 56Ω 560Ω 5.6kΩ 56kΩ 560kΩ 5.6MΩ 6.2Ω 62Ω 620Ω 6.2kΩ 62KΩ 620KΩ 6.2MΩ 6.8Ω 68Ω 680Ω 6.8kΩ 68kΩ 680kΩ 6.8MΩ 7.5Ω 75Ω 750Ω 7.5kΩ 75kΩ 750kΩ 7.5MΩ 8.2Ω 82Ω 820Ω 8.2kΩ 82kΩ 820kΩ 8.2MΩ 9.1Ω 91Ω 910Ω 9.1kΩ 91kΩ 910kΩ 9.1MΩ #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed capacitor ideal for rapid circuit topology development. You can choose between polarized and non-polarized types, its symbol and the footprint will automatically adapt based on your selection. Supported options include standard SMD sizes for ceramic capacitors (e.g., 0402, 0603, 0805), SMD sizes for aluminum electrolytic capacitors, and through-hole footprints for polarized capacitors. Save precious design time by seamlessly add more information to this part (value, footprint, etc.) as it becomes available. Standard capacitor values: 1.0pF 10pF 100pF 1000pF 0.01uF 0.1uF 1.0uF 10uF 100uF 1000uF 10,000uF 1.1pF 11pF 110pF 1100pF 1.2pF 12pF 120pF 1200pF 1.3pF 13pF 130pF 1300pF 1.5pF 15pF 150pF 1500pF 0.015uF 0.15uF 1.5uF 15uF 150uF 1500uF 1.6pF 16pF 160pF 1600pF 1.8pF 18pF 180pF 1800pF 2.0pF 20pF 200pF 2000pF 2.2pF 22pF 20pF 2200pF 0.022uF 0.22uF 2.2uF 22uF 220uF 2200uF 2.4pF 24pF 240pF 2400pF 2.7pF 27pF 270pF 2700pF 3.0pF 30pF 300pF 3000pF 3.3pF 33pF 330pF 3300pF 0.033uF 0.33uF 3.3uF 33uF 330uF 3300uF 3.6pF 36pF 360pF 3600pF 3.9pF 39pF 390pF 3900pF 4.3pF 43pF 430pF 4300pF 4.7pF 47pF 470pF 4700pF 0.047uF 0.47uF 4.7uF 47uF 470uF 4700uF 5.1pF 51pF 510pF 5100pF 5.6pF 56pF 560pF 5600pF 6.2pF 62pF 620pF 6200pF 6.8pF 68pF 680pF 6800pF 0.068uF 0.68uF 6.8uF 68uF 680uF 6800uF 7.5pF 75pF 750pF 7500pF 8.2pF 82pF 820pF 8200pF 9.1pF 91pF 910pF 9100pF #generics #CommonPartsLibraryjharwinbarrozo1.5M

- A generic fixed inductor for rapid developing circuit topology. *You can now change the footprint and 3D model at the top level anytime you want. This is the power of #genericsjharwinbarrozo15.1k

- An electrical connector acting as reusable interface to a conductor and creating a point where external circuits can be connected.Terminal

- 47 kOhms ±5% 0.125W, 1/8W Chip Resistor 0805 (2012 Metric) Automotive AEC-Q200 Thick Film #forLedBlinkjharwinbarrozo1.2M

- 10uF Capacitor Aluminum Polymer 20% 16V SMD 5x5.3mm #forLedBlink #commonpartslibrary #capacitor #aluminumpolymer #radialcanjharwinbarrozo1.2M

- Yellow 595nm LED Indication - Discrete 1.7V 1206 (3216 Metric) #forLedBlinkjharwinbarrozo1.1M

Inspect

BRAVE POWER MANAGEMENT BOARD

Controls

Properties

Availability & Pricing

| Distributor | Qty 1 | |

|---|---|---|

| Arrow | $0.81–$2.17 | |

| Digi-Key | $0.73–$2.82 | |

| LCSC | $1.72–$2.90 | |

| Mouser | $3.10–$3.73 | |

| Verical | $0.48–$1.96 | |

Assets

- power_manager_board-removebg-preview.png

id=power_manager_board-removebg-preview

- qrcode.svg

id=qrcode

- flux logo.svg

id=flux logo

- qrcodev2.svg

id=qrcodev2

- power manager board.png

id=power manager board

Thumbnail

Default

Welcome 👋

Flux helps you build PCBs faster with an AI teammate!

Create your account to collaborate, stay updated, fork your own version, and get instant answers from our AI agent.